CPE Alloys

CPE Alloys Push the Limits of Performance for Wire & Cable Applications

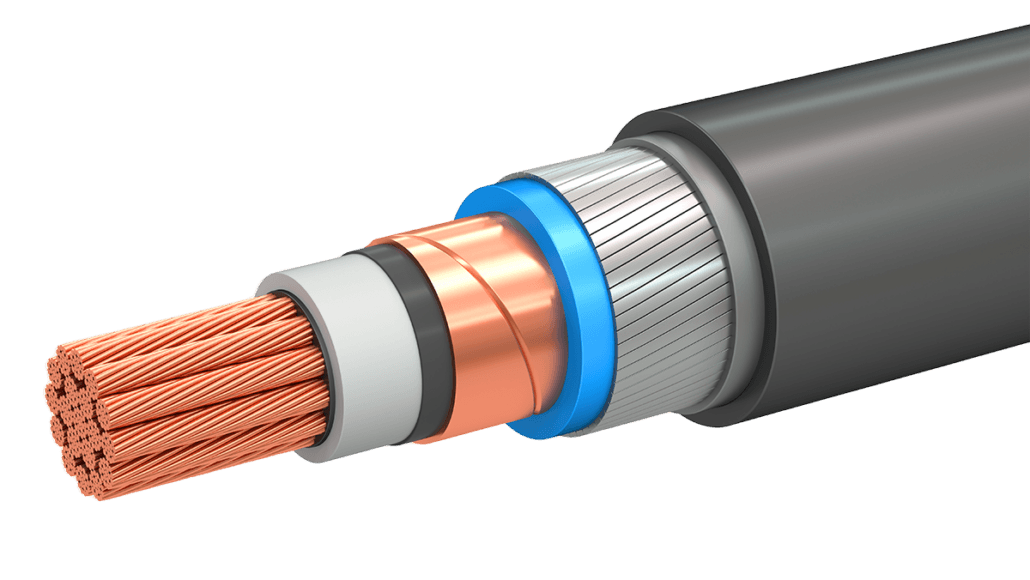

From the freezing cold of the arctic tundra to the intense heat a motor can generate, wire and cable polymer compounds are tasked with performing in some of the most brutal conditions on the planet. Beyond the temperature extremes, wire and cable compounds have to withstand chemicals, harsh environments and abrasive forces. Whatever challenges wire and cable applications bring, the polymer compounds in them have to meet demanding performance criteria.

Wire and cable compounds can include PVCs, polyolefins, fluoro polymers, silicone and many more. These compounds offer exceptional performance, but can be cost prohibitive in certain applications. PVC offers a lower price point, but doesn’t offer the same robust performance properties.

CPE (chlorinated polyethylene elastomer) alloys are a more economical solution

CPE (chlorinated polyethylene elastomer) alloys don’t have to sacrifice performance for a lower price point. CPE is produced by chlorination of polyethylene, with chlorine content ranging from 15 to 30% by weight. CPE has excellent physical and mechanical properties, such as resistance to oils, chemicals and improved thermal properties. CPE polymers can also exhibit better compression set, flame retardancy, tensile strength and abrasion resistance, and can range from rigid thermoplastics to flexible elastomers, making them highly versatile.

CPE blends well with many types of plastics

CPE blends well with polyethylene, EVA, and PVC. Such blends can be formed into wire and cable compounds with good dimensional stability without the need for vulcanization. The excellent additive/filler acceptability characteristics of CPE can provide a benefit in blends where compound performance and economics are critical.

Our CPE offering portfolio can be categorized into three groups.

- Blends of CPE and Vinyl, which produce very robust compounds with exceptional oil resistance, physical and flame characteristics. If the environments contain oil, acids or alkalis, CPE jackets give more protection than PVC.

- TPO based CPE, with very low halogen content, superior low temperature properties and good flame characteristics.

- CPE systems suitable for radiation crosslinking. They are oil resistant, flame retardant, E-beam curable, CPE based compounds suitable for wire & cable applications. Custom color matching is available.

CPE (Chlorinated Polyethylene) Alloys

CPE is the standardized acronym for thermoplastic chlorinated polyethylene elastomer, which is produced by chlorination of polyethylene. The chlorine content can be 15 to 30% by weight.

Durable & Long-lasting

Chlorinated polyethylene elastomers (CPE) and resins have excellent physical and mechanical properties, such as resistance to oils, chemicals, and improved thermal properties. They can also exhibit better compression set, flame retardancy, tensile strength and abrasion resistance.

Highly Versatile

CPE polymers can range from rigid thermoplastics to flexible elastomers, making them highly versatile. These polymers are used in a variety of end-use applications such as wire and cable jacketing, roofing, automotive and industrial hose and tubing, molding and extrusion, and as a base polymer.

Improved Durability & Stability

CPE blends well with many types of plastics such as Polyethylene, EVA, and PVC. Such blends can be formed into final products with adequate dimensional stability without the need of vulcanization. The excellent additive/filler acceptability characteristics of CPE can provide a benefit in blends where compound performance and economics are critical.