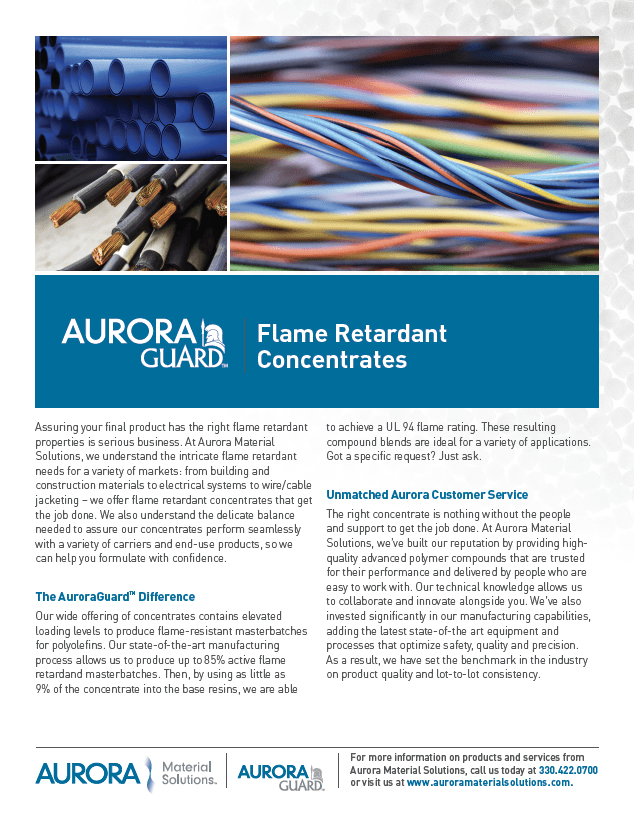

Flame Retardant Concentrates

Aurora Material Solutions offers a portfolio of concentrates that includes more than 20 formulations.

The goal of concentrates is the ideal dispersion of additives in the polymer matrix. The fine, powdery feed material often tends to agglomerate and is therefore difficult to work with. Concentrates (masterbatches) with an additive share of 20 – 85% are available, depending on the feed material.

Using masterbatch increases the process stability. Additionally, since there is no handling of large powder masses, the environment and the work station remain clean.

Our portfolio of concentrates is divided into five main categories:

- Flame Retardant (FR)

- Ultraviolet (UV)

- Expandable

- Odor Masking

- Desiccant